Mill Stand machines are for forming products 60mm high or above. Each pair of top and bottom roll shafts is individually carried on sealed-for-life ball bearings within the adjustable bearing blocks of the individual cast support stand. These blocks are vertically adjustable within the stand for roll height and material gauge gap. The top block adjusting screw is fitted with a graduated display relating to the nip gap between the rolls. The mill stands are supported and key located on base plates which can either be rafted or part of the main fabricated support frame. The frame mounted helical geared motor transmits the drive via gears to the main bottom roll shaft, which in turn transmit through idler gears to the remaining bottom shafts. Each drive base can carry up to six forming stands and are bolted and jacked to allow accurate alignment.

Trapezoid roof forming machine: Complete line to make the roof forming machine, according to customer's requested profile drawings. Working schedule:5 ton decoiler------Guiding ------Main forming machine-----hydraulic cutting device-------Simple run out table----PLC Control system

PRODUCT DESCRIPTION

Components:

5 ton hydraulic decoiler

Guiding and filming device( with rubber roller)

Main forming machine

hydraulic cutting device

Hydraulic station

PLC Control system

Simple run out table

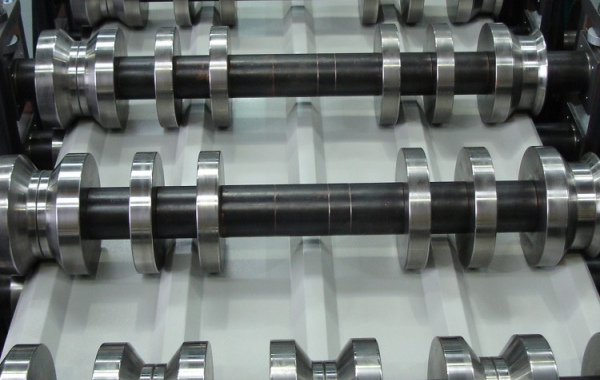

Details main machine

1) Suitable material: pre-painted galvanized steel or Aluminum. material thickness: 0.3~0.8mm

2) Forming speed: 15meters/min

3) Forming stations: 18~25 stations (According to customer's requested profiles)

4) Roll material: 45# steel with heat treatment and chrome plating on surface, Hardness: HRC58~62

5) Shaft material: 45# steel with heattreatment. (Dia: 76mm)

6) Main machine motor power: 5.5KW~7.5KW

7) Cutting: Hydraulic cutting

8) Cutting blade material: Cr12Mov, HRC58~62

9) Control system: The whole machine is controlled by PLC,

The production process:

5ton decoiler—→Guiding device—→Roll-forming Machine—→Hydraulic cutting —→simple run out table