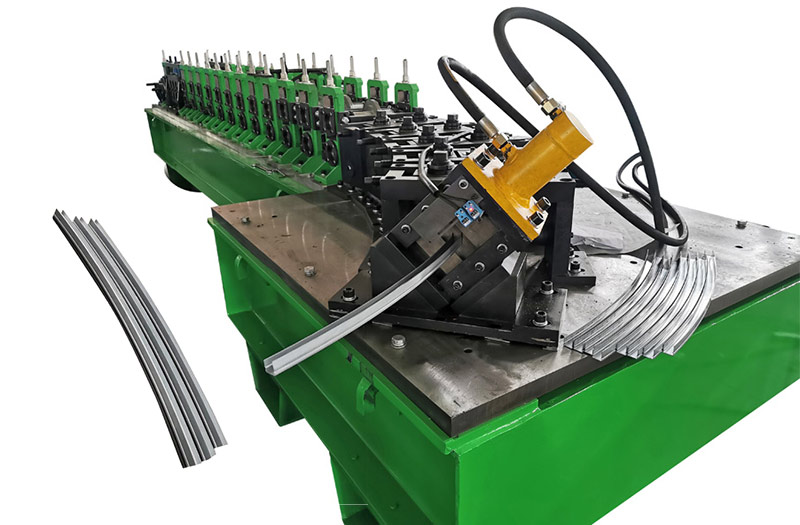

The forming of the profile being performed very gradually, we do not have to fear the cracks or even the breaks that occur in the cold bending to the press or stamping.Finally, although it is not a rolling, the operation produces a certain surface hardening known as the "skin effect".The manufacturing, initially limited to hot and cold rolled steel strip sections, has gradually expanded to include stainless steel and aluminum and copper alloy profiles.

During the cold roll forming, operations such as punching, stamping, can be done online.Then, the metal section is cut at the end of the line to the desired length.The profiling operations are performed cold, because carried out at room temperature, they do not require the heating or melting of the metal for the manufacture of a profile.

The cold roll forming operation does not bring about any substantial modification to the flat product used concerning its thickness and its mechanical characteristics.The cold forming industry is part of the primary metal processing industry between the steel industry and users.

The cold roll forming advantages are numerous :

Development, diversity and complexity of forms that meet all the needs of users.

Curvature radius corresponding to the thickness of the metal strip.

Lightening the weight of structures by roll forming steels with high elastic limits.

Ease of implementation in assemblies with welding, riveting, bolting, gluing.

Variety of possible delivery lengths of steel profiles, up to 30 meters.

Diversity of surface conditions such as hot roll, pickled, cold rolled, prepainted, and galvanized.